&

NEWS

Franklin Electric Names New VP, CFO

Fort Wayne, Indiana-based Franklin Electric Co. Inc. has named Jeffery L. Taylor to the role of vice president and chief financial officer. The move was effective June 14, 2021.

“Jeff brings strong financial leadership, operational expertise and public company experience to Franklin Electric,” says Gregg C. Sengstack, CEO and chairman of Franklin Electric. “His deep experience in supporting commercial and manufacturing organizations and proven track record of driving change that supports long-term value creation will be invaluable. I look forward to his unique perspective and skills contributing to our outstanding leadership team.”

Taylor assumes the role from John J. Haines, who is retiring. Haines committed to assist Taylor through an interim period to ensure a seamless transition.

Caption: Jeffery Taylor joins Franklin Electric from Blue Bird Corporation. Source: Franklin Electric

“John Haines joined Franklin Electric in 2008, during the height of the financial crisis,” Sengstack adds. “He has led our finance organization through a period of significant growth, both organic and inorganic. As a key member of the Franklin leadership team, he had a significant impact on our strategic direction and made many contributions to our company.”

Most recently, Taylor served as CFO of Blue Bird Corporation, a manufacturer of school buses, a role he began in 2020. He had previously been senior vice president and CFO of Wabash National Corporation from 2014 to 2020. Taylor has also worked in multiple financial positions with King Pharmaceuticals and Eastman Chemical Company.

Taylor holds a bachelor’s in chemical engineering from Arizona State University and an MBA from the University of Texas.

Franklin Electric offers an array of systems and components for moving water and automotive fuels. It serves residential, commercial, agricultural, industrial and municipal customers around the world. For more information, visit www.franklinwater.com.

Red Rock Hydroelectric Facility Wins 2021 DFI Outstanding Project Award

Caption: The Deep Foundations Institute is honoring the Red Rock Dam teams due to the project’s many geotechnical and other challenges. Source: DFI

DFI will present the award during the 46th Annual Conference on Deep Foundations, Oct. 12-15, 2021, in Las Vegas.

In a release, the group says companies on the project overcame many geotechnical and other challenges, including constructing a new intake channel, penstocks that carry water to the turbines, and a powerhouse directly adjacent to the existing dam’s spillway. Teams on the project used extensive water- and earth-retention systems, prescriptive construction staging, and a robust dam safety surveillance program to maintain the dam’s integrity during construction. The key foundation elements and excavation features included diaphragm walls, deep excavations and treatment of solutioned gypsum deposits.

The U.S. Army Corps of Engineers’ facility near Pella, Iowa, now provides up to 55 MW (55,000 kW) of clean, reliable power to surrounding communities, and will generate 178,000 MWH (178,000,000 KWH) annually.

Special recognition awards will also be given to two other entries: Little Island Pier 55 at Hudson River Park in New York City, in which Mueser Rutledge Consulting Engineers designed hybrid piles for an undulating landscape that required exacting pile locations and extremely tight pile cutoffs; and PB&A for the complex shoring wall design for 2nd Street/Broadway rail station, with challenges that included maintaining live traffic during excavation, supporting heavy underground utilities, and the protrusion of the Los Angeles Times Building into the station.

The OPA was established in 1997 to recognize the superior work of DFI members. A committee selects the projects based on size, scope and challenges of the project; degree of innovation and ingenuity exercised; and uniqueness of the solution to the difficulties of the job.

The DFI is an international association of contractors, engineers, academics and suppliers in the deep foundations industry with more than 3,500 members worldwide. For more information about the Deep Foundations Institute, visit www.dfi.org.

The Deep Foundations Institute has awarded this year’s Outstanding Project Award to a team of companies working on the Red Rock Dam. In a release, the DFI applauded the “ingenuity” of the design and work put in to modify the dam over Iowa’s Des Moines River into a hydroelectric facility.

The team on the project included:

Stantec (engineer)

Ames Construction (general contractor)

Case-Bencor JV (Keller; foundation)

Missouri River Energy Services (owner)

Rembco Geotechnical Contractors (grouting)

And Schnabel Geostructural Design & Construction (anchoring)

UMA Preserves Retaining Wall Structures for N.C. Bridge Demo

“Throughout the duration of this project,” says UMA President Brian DeSpain, “UMA was faced with two main challenges in order to properly and safely install the anchors.”

First, the UMA crew had to attach the top of the anchors through the existing bridge deck in order to achieve the proper installation angle. The bridge itself obstructed access for the work from below.

UMA used duplex drilling to advance both casing and drill steel into each hole simultaneously to keep them from collapsing. After reaching the required 30- to 50-foot hole depth, UMA installed 30- to 54-foot anchors inside the steel casing, with lengths varied based upon location and bar sizes of either #6 or #11.

The bar system that UMA used also incorporated double corrosion protection, specifically Multiple Corrosion Protection (MCP) bars. This type of Class 1 corrosion protection consisted of a bare bar surrounded by a corrugated plastic sheath, which was large enough to allow it to be filled with grout and provided a three-inch solid casting of grout around all sides of the bar. After the hole was drilled to the proper depth, the bar and a tremie tube were placed into the hole, and the hole was completely grouted to the face of the wall.

After the proper grout curing time, the anchors were cyclically load-tested to the specified loads. At the end of the load tests, the anchors were locked off at 50 percent of the designed load in order to engage the anchor.

The second challenge was that the two retaining walls are positioned on either side of an active creek, fed by the nearby Lasater Mill Pond. To achieve the correct anchor installation position, UMA opted to use a semi-elevated platform constructed using crane mats. This allowed field technicians to use the appropriate drill angle while water flowed freely in the creek.

“The successful completion of any project relies on the management and technical skills of the construction team, both in the office and on site,” DeSpain says. “It’s because of the expertise and teamwork of the employees at UMA that the retaining walls were able to be properly secured, a critical step to a safe bridge demolition.”

UMA Geotechnical Construction Inc., a leading developer of polymer grouting techniques, works to save clients money with specialized ground engineering solutions. The UMA team, which includes experts in structural support, earth retention and soil stabilization, was among the first to use lightweight structural polymers to improve subsurface soils at depths greater than 40 feet. For more information, visit www.team-uma.com.

.

Caption: UMA Geotechnical Construction successfully secured two existing retaining walls in the Winston-Salem area to allow demolition of an existing bridge to move forward. Source: UMA Geotechnical Construction

North Carolina-based UMA Geotechnical Construction this spring helped a customer avoid failure of retaining wall structures during the demolition of a bridge spanning Blanket Creek in the Winston-Salem area.

UMA, under subcontract to Kernersville, North Carolina-based National Bridge Builders, installed 14 ground anchors on two retaining walls held in place by the span targeted for demolition. These walls could have collapsed if not properly secured independently prior to demolition. Traffic had already been rerouted to the new replacement bridge.

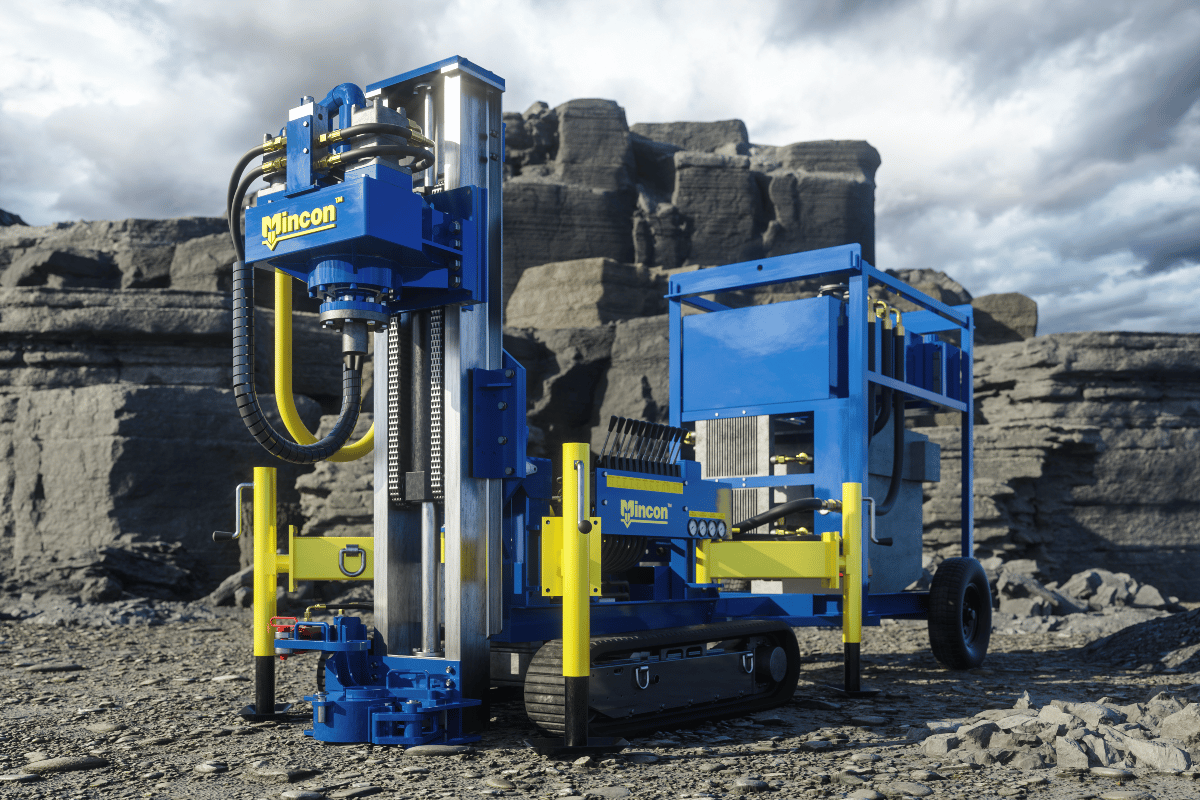

Mincon Releases New Modular Rock Drill Systems

Mincon says the new Rock Drill mast attachments offer drillers cost-effective and attainable entry into the drilling market by using an attachment to existing equipment, whether it’s an excavator, skid steer or another compatible carrier machine. Mincon calls the standalone drilling rigs in the Rock Drill range “compact and versatile self-powered systems for customers who want to expand their fleet with dedicated drilling solutions that have a smaller footprint than conventional drill rigs.”

The full Rock Drill product line comprises three drill rigs and five drilling mast attachments. The R405, R412 and R512 drill rigs use a sub-90 horsepower powerplant and are compatible with 3-, 5- and 10-foot drill rods, respectively (or 1-, 2- and 3-meter drill rods in the European market).

The M106, M112 and M120 drilling mast attachments share a design, with each model representing a different length. The M207 and M220 drilling mast attachments have a heavy-duty design to accommodate the power requirements of deep-hole drilling.

The company says all Rock Drill drilling mast attachments and rigs offer guaranteed compatibility with Mincon’s existing range of drilling solutions and accessories, including the company’s DTH hammers and DTH drill bits; Spiral Flush geotechnical drilling systems; rotary drill bits; and drill pipe.

The new product line has been made possible by Mincon’s acquisition of Hammer Drilling Rigs in January 2021. The Rock Drill line of drill masts and rigs is based on proven, modular designs that have been fine-tuned over the last four decades. Mincon says it has further developed and engineered the original designs to provide greater functionality and reduce environmental impact during manufacturing.

“As drillers, our engineering philosophy has always been centered on the end user’s needs: equipment that’s easy to use, with low maintenance costs, utilizing readily available off-the-shelf parts,” says Simon Duck, senior engineer, Integrated Systems, Mincon Group. “Our aim has been to include innovative simplicity in our solutions, which ultimately makes them tougher and last longer.”

For more information, visit www.mincon.com/rockdrill.

Caption: The Rock Drill lineup includes three drill rigs with sub-90-horsepower powerplants. Source: Mincon Group

Mincon has unveiled its Rock Drill series of compact, modular drill mast and drilling rig systems. In a release, the company says the series is designed to complement its existing range of rock-drilling solutions.

“The introduction of these modular systems is a great step forward for Mincon, allowing new customers to affordably enter the rock-drilling industry and benefit from the performance and efficiency of our class-leading solutions,” CEO Mincon Group Joe Purcell says.